Description

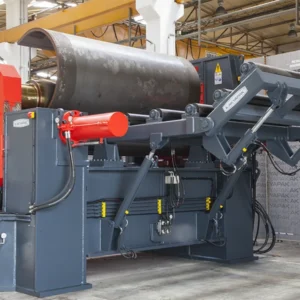

AKYAPAK also provides a wide range of options for high duty profile bending machines. With its St-52 weld construction body, our machines are sturdy and dependable. Because of our machines’ larger roll diameters, little bending results in less distortion. Durability and high bending momentum may be produced by using large bearing dimensions.

The strength of hydraulic cylinders allows for easy bending of bigger pieces. Practical and universal rollers provide for more ease in bending diverse portions, and this characteristic allows for greater power and robustness.

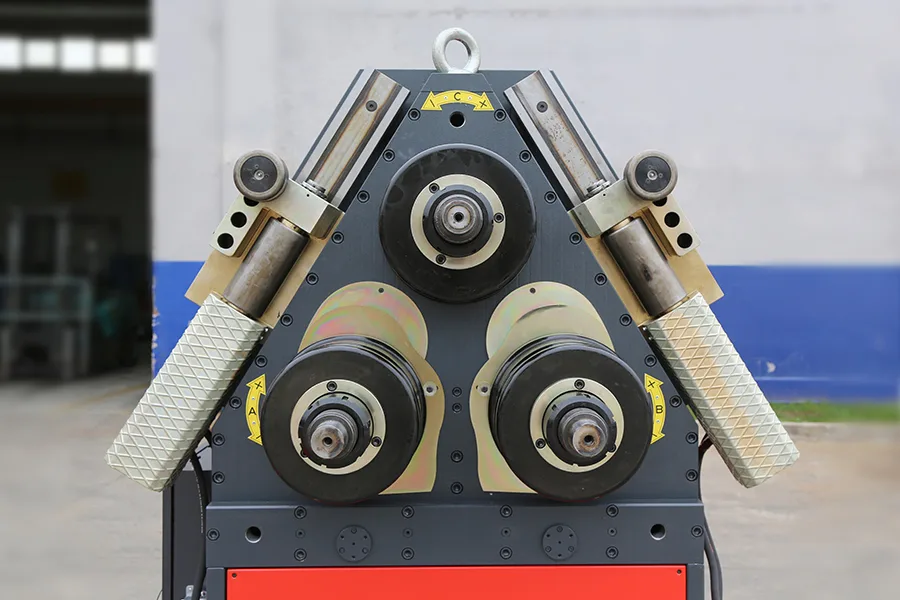

The Akyapak Profile Bending Machines have three rollers. This property enables the potential of implementing large capacity bending procedures. Second, the 3 Rolls Driven machine reduces material slippage during the bending process. The two bottom rollers are hydraulically powered and may move independently of one another.

As a result, as compared to top roll drive machines, the characteristics of our machines boost operator skill and provide the capacity to do prebending on both edges. Side supports can move in three directions to lessen deformations and make bending operations easier, particularly with angles and spirals.