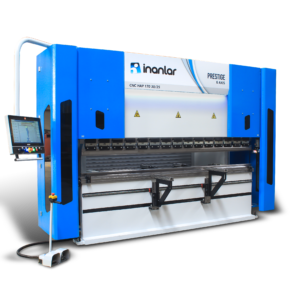

Description

Flagship sheet fiber laser metal cutting machine

10kW+ Cutting Process Package

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Automatic Nozzle Changer

The fiber laser nozzle changes within 35 seconds at the soonest, 50% of time costs saved.

Intelligent Over-heat Adaptation

Over-heat adaption ensures stable thick plate cutting by compensating focus automatically to solve “temperature drift” when cutting carbon steel.

Active Anti-collision Function

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

One-click Processing

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing

One-click Processing

The whole lightning-quick piercing process completes during BodorGenius moves down on Z-axis. With the process, reworking is avoided for medium/thick sheet piercing.

Mechanical Configuration

Maglev Linear Motor

The “magnetic levitation theory” based linear motor drive which collaborates with BodorThinker4.0, the bus control system, generates no mechanical friction, makes maintenance easier, and improves greatly precision, steadiness, speed and efficiency.

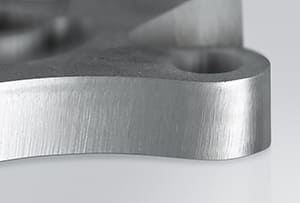

Marble Machine Bed

The high vibration absorption and low heat sensitivity of the cutting machine marble bed ensure little impact from vibration and heat during processing on laser cutter accuracy.

Carbon Fiber Crossbeam

Carbon fiber has a two-thirds density of aluminum alloy but owns 21 times stronger tensile strength. Therefore, the laser cutter crossbeam impresses with its improvement for better dynamic performance of equipment.

Fully Closed-loop Position Detection

The fully closed-loop position detection keeps laser cutter accuracy and precision by ensuring that the actual motion position is consistent with the theoretical input value.