Description

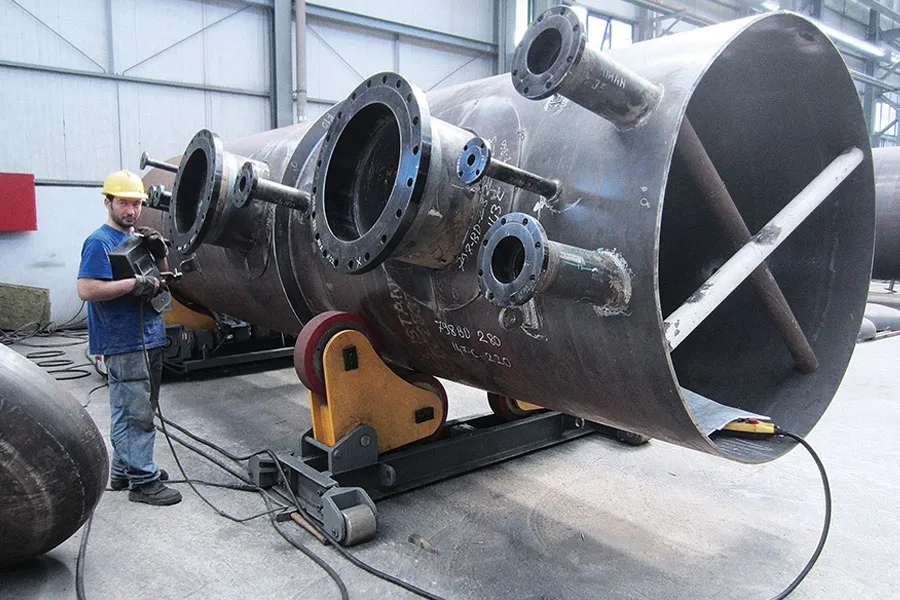

SAR

Self-aligning rotators are appropriate for situations where the diameter of the rotating work parts varies. Tanks, pressurized containers, tower pipework, boiler, silos, reactors, fuel drums, and other revolving circular elements. These rotators can automatically change a broad variety of diameters. There is no additional time or effort necessary to begin rotating the work piece.

Rotators increase welding speed and efficiency during both automatic and manual welding, and they play an essential role in steel building workshops by reducing crane operation.

The parts put on the rotator may be rotated clockwise or counterclockwise, accurately, well-aligned, and controlled through control panel at readily changeable rates. Self-aligning rotators are made up of two units: one drive and one idler. The number of driving and idle units can be varied depending on the application.

Akyapak Makine’s main product line comprises self-aligning rotators ranging in size from 3 to 300 tonnes. However, bespoke manufacture of up to 600 tonnes is possible.