Description

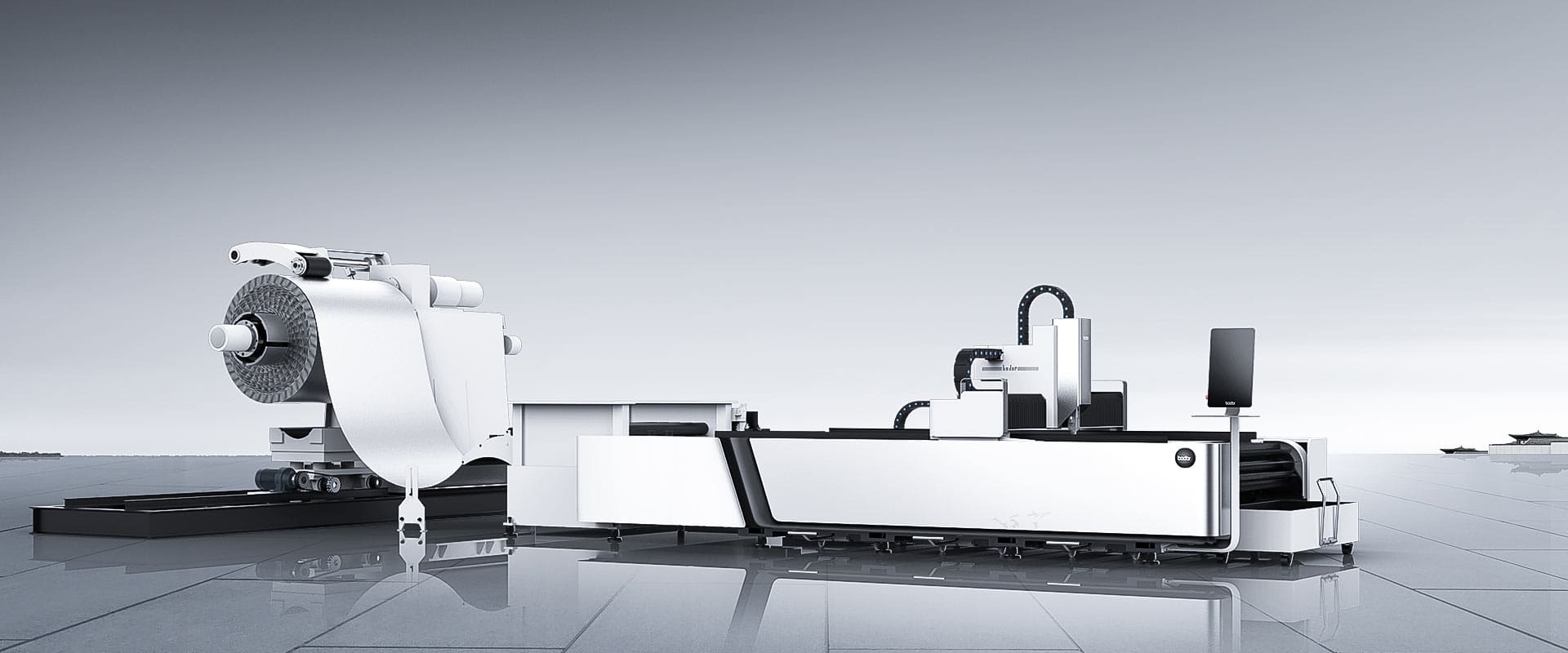

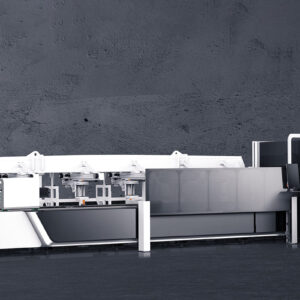

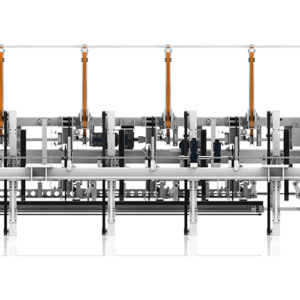

Fully automated coiled sheet fiber laser production line

Function Enhancement

Expert High Speed Cutting Database

Fast air cutting efficiency increases by 37% when cutting carbon steel.

Active Anti-collision Function

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

Bodor Lightning

The lightning-quick piercing process combined perfectly with BodorGenius completes the whole piercing just during the laser cutter head moves down on Z-axis.

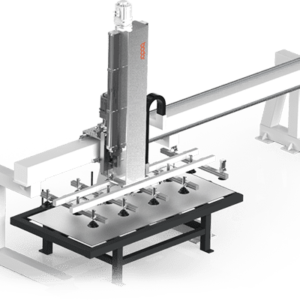

Automated Loading

Equipped with the hydraulic trolley, the cutting machine provides automated feeding of coils in no need for manual work.

Mechanical Configuration

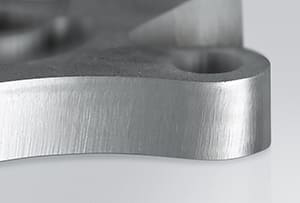

Cast Iron Bed

Flake graphite in the cutting machine bed improves greatly the shock absorption and wear resistance, and residual stress almost disappears after age hardening, therefore, precision and lifetime of the equipment are improved, and costs saved.

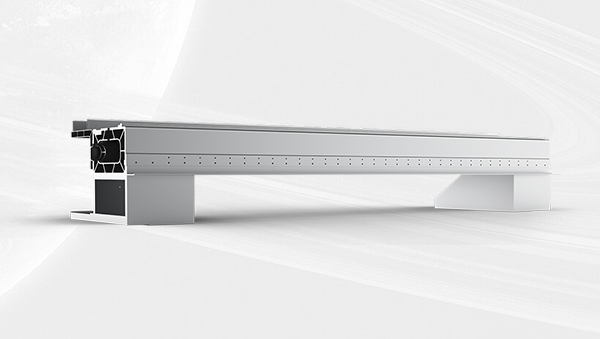

Stretching Aluminum Crossbeam

Ultra-high-pressure stretching process and lightweight design; Rigidity increases by 60% ; Weight goes down by 20% ; Laser cutter running speed increases by 50%

Efficient and scratch-avoiding rotatable slats

Rotatable slats on the laser cutting machine bed rotating synchronously with the uncoiler and leveller avoids scratches and increases processing efficiency and quality.